ScottMadden assisted a large Midwestern investor-owned utility to improve its supply chain organization’s strategy, governance, and operations including the supply chain organization’s relationship to the business units it supports.

The company did not have a focused supply chain strategy company-wide. Costs were high and the organization could not provide the strategic direction needed for efficient planning, sourcing, and materials management across the company.

Supply chain was viewed differently by each business unit and had to conform to provide the level of service expected by different internal customer groups. The supply chain organization was seen as a transactional service provider instead of a partner.

Additionally, the client’s supply chain strategy was fragmented, and there was no clear answer to what role the supply chain organization played and how individual business units should enable it. Due to the “siloed” manner in which the business units operated, there were no clear, concise, and customer-oriented processes for supply chain activities put into place, including item file management, spend categorization, and materials management. The absence of standardized processes to guide sourcing and procurement activities across the enterprise created unnecessary administrative workloads and led to increased costs.

Finally, there was a high level of turnover at both the supply chain leader and individual contributor levels, which added to the confusion regarding supply chain’s role. Each of these symptoms contributed to a high number of transactions, shifting the supply chain organization’s focus away from identifying more value-added opportunities.

First, ScottMadden helped the client to articulate one clear enterprise strategy for supply chain management, which senior executives could support, drive, and monitor.

Early in the project, ScottMadden formed an executive steering team of key leaders to champion the transformation process. Refined processes provided the foundation, but change management, led by the company’s senior leadership, was critical to achieve a successful outcome. Additionally, ScottMadden identified a small core team of key supply chain representatives and business unit customers and educated them on leading practices. These collaborative workshops with the core team identified key “pain points” in the organization (from both supply chain’s and the business unit’s perspectives), defined future state attributes required to address the pain points, and established roles and responsibilities between supply chain and the business units, so each could focus on their core competencies. ScottMadden then reviewed current state policies, processes, and procedures and identified gaps.

Second, the ScottMadden team also helped create alignment between business units and supply chain in support of that strategy. The figure below displays this transformation.

The team developed a refined policy/process framework to enable the future state strategy. This included the definition of key supply chain and business unit/area metrics, roles and responsibilities, and accountabilities. To guide the rollout of the new framework, ScottMadden also created an implementation and change management plan to transition and implement the recommended changes. This plan emphasized communication and “quick wins” to provide the foundation for effective organizational change. It also included the identification of a small selection of performance measures to enable the future state. These performance measures not only tracked how well the supply chain was providing service, but also how well the overall business was performing in achieving the future state strategy (e.g., timeliness, asset/inventory performance, and financial metrics).

The three-month implementation phase of the project focused on the development of a Supply Chain Management Model, which consisted of a series of policies, processes, and procedures designed to align supply chain operations with the new strategic direction. As displayed in the figure below, The Supply Chain Management Model was divided into four functional areas that spanned the responsibilities of the supply chain: 1) planning and forecasting, 2) strategic sourcing and procurement, 3) materials management and logistics, and 4) governance.

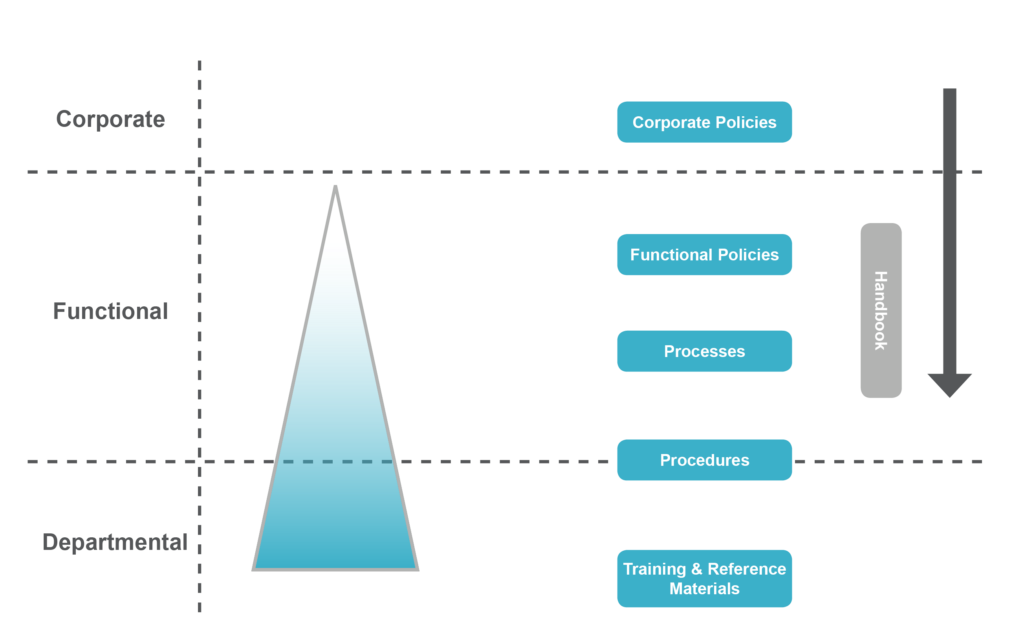

For each of the four functional areas, ScottMadden assembled a development team, reengineered the processes so they aligned with the business strategy, and created a new supply chain handbook for all business unit employees. The handbook was designed from a business unit perspective and presented critical information employees needed to know to interact with supply chain. Example topics included how to buy an item, how to request a service, and how to work with supply chain during planning and forecasting.

ScottMadden was able to reopen communications that had previously broken down between the business units and supply chain. The team created one clear enterprise strategy for supply chain management and identified opportunities to reduce costs through improved category and inventory management. ScottMadden also identified five “quick wins” that made an immediate impact by streamlining work and reducing costs, all while establishing support for the supply chain transformation.

Category management represented the greatest opportunity for cost savings. ScottMadden recommended that spend teams be put in place to assess purchasing needs by category, analyze market data and total cost of ownership, and determine the most effective sourcing strategy. Instilling strict vendor management processes on the back end was also critical to success. Based on a conservative estimate for non-environmental and non-project spend, implementation of the recommendations could produce recurring annual savings of approximately $1.7MM–$2.8MM.

A second opportunity to reduce costs was to streamline inventory management. The lack of centralized control and statistical analysis of inventory levels increased the amount of inventory needed to meet service levels. Inventory could be reduced with the proper statistical analysis that would produce considerable savings, increase efficiency, and improve standardization and visibility of material. Plant reliability would also be improved by ensuring that the right parts were in the right place at the right time. This recommendation fit into the client’s overall cost reduction and operational improvement strategy.

Going forward, the institution of an effective Supply Chain Management Model will help clarify roles and responsibilities between supply chain and the business units. It will also help the supply chain organization move away from its previous transactional focus to one that balances transactional efficiency with the pursuit of strategic opportunities that provide greater value to supported business units.

View MoreSussex Economic Advisors is now part of ScottMadden. We invite you to learn more about our expanded firm. Please use the Contact Us form to request additional information.