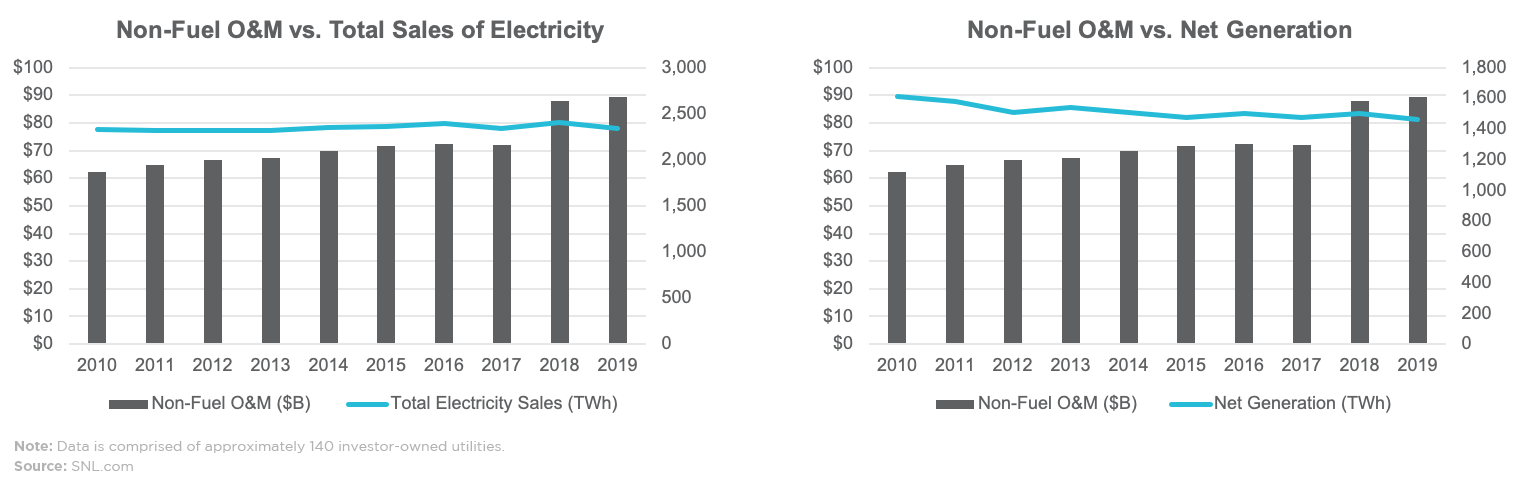

Slow economic and demand growth coupled with increased penetration of distributed energy resources (including energy efficiency) has resulted in declining energy industry sales and revenues. Many companies have witnessed their non-fuel O&M costs increase in the face of rapidly declining generation and sales, creating an unsustainable environment (see charts below). To avoid increasing energy rates and further eroding sales, companies are looking to reduce costs to meet shareholder expectations. This document provides an overview of the steps that you can take to achieve sustainable cost reductions.

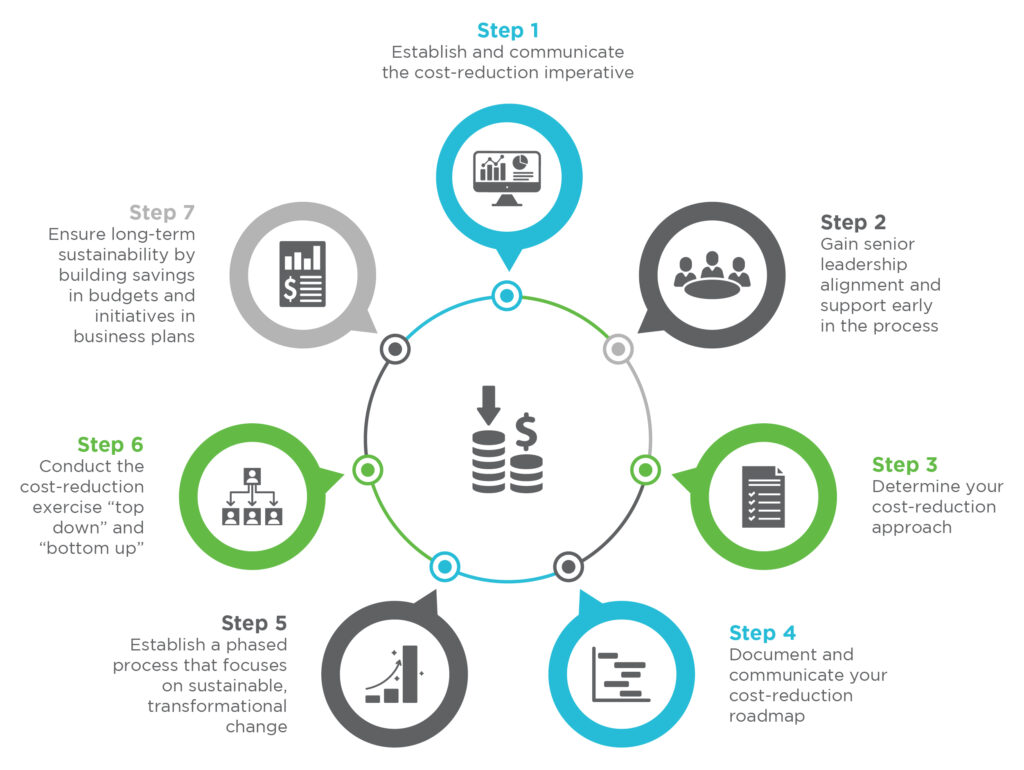

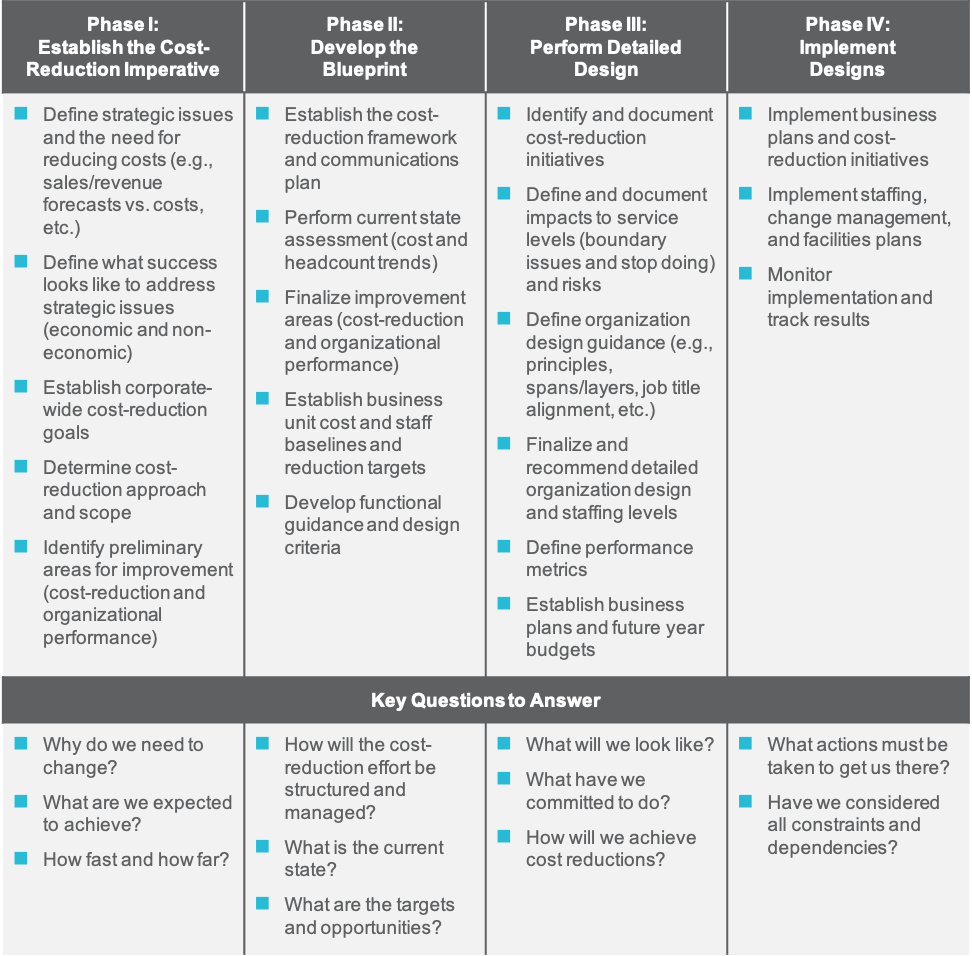

To achieve significant, sustainable savings a methodical approach is important. The proven seven-step approach described below showcases the importance of the right steps in the right order to make the biggest impact.

![]()

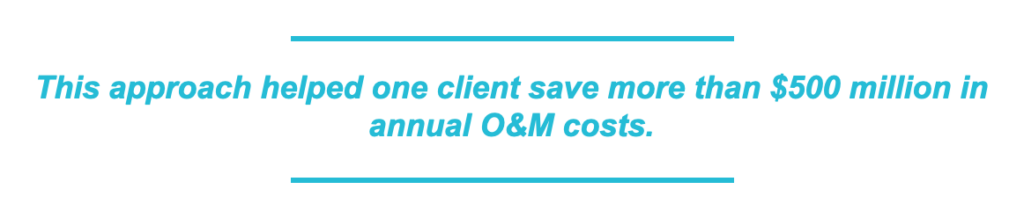

Establishing and communicating an easily understood imperative will help to ensure buy-in at all levels. One approach is simply illustrating the unsustainable environment of increasing costs relative to flat to declining revenues (see charts above). Another approach is using shareholder expectations to help to communicate the need for cutting costs (e.g., comparing management aspirations for earnings per share (EPS) to industry and/or analyst expectations—see example chart below). The gap between the analysts/industry forecasts and management’s EPS goals can be converted to cost-reduction and revenues requirements and highlight the need to further reduce costs.

![]()

Conducting a cost-reduction planning workshop with senior leadership will ensure alignment and support for the cost-reduction process. When preparing for the workshop, you should consider the objectives as well as the outcomes and deliverables you want to achieve. Examples are shown below.

![]()

Four cost-reduction approaches are predominant. Each approach varies as to its ideal application and time to implement.

Often, the best cost-reduction approach for an organization can be crafted using elements of each of the methods. Regardless of the cost-reduction method, an ideal approach should:

![]()

To achieve buy-in to the changes, it is important to clearly document and communicate the reasons, plans, and timing of the initiative. Consider these elements in your communications:

Imperative and Objectives

Decisions Already Made

Critical Success Factors and Principles

Approach, Process, and Timeline

Implementation Priorities and Critical Milestones

Management Structure and Roles

![]()

![]()

Using both a top-down and bottom-up approach allows you to create the most successful and sustainable plans by providing guidance and expectations while depending on your people to deliver on the details.

|

Senior leadership should set the top-down expectations by first selecting the expected approach to complete the exercise. Next, they should define the timelines required for the process and set targets/parameters on cost savings and organizational changes. |

|

Functional teams should build the plans bottom-up by using top performers from multiple levels of the organization. The team should identify the future managers of a function and involve them in the process, as possible. It is important to provide the teams the resources and latitude they need to be successful and encourage new approaches and ways of thinking. |

|

Final plans should be challenged by the leadership team prior to approval. Leaders from each functional area should present their approach and encourage peers from other functions to question and challenge everything, including plans, assumptions, targets, etc. During this challenge period, ensure everyone is maintaining an open mind, and adjust plans as needed. |

![]()

If planning and expertly executing cost-reduction initiatives is a priority for you, ScottMadden can help. Support for cost-reduction initiatives has been one of the core competencies of ScottMadden since our founding in 1983. Recently, we assisted a large electric utility client in saving more than $500 million in annual O&M costs, and we have conducted myriad executive-level leadership team cost-reduction planning workshops. With significant experience assisting companies to successfully design and implement integrated operating models, our functional expertise in the energy industry is deep, and our consulting experience is broad—a combination we believe is unique in the consulting industry.

Contact us to discuss any questions you may have or how to get started on a cost-reduction approach for your organization.

Sussex Economic Advisors is now part of ScottMadden. We invite you to learn more about our expanded firm. Please use the Contact Us form to request additional information.