While most industry professionals agree that effective inventory optimization is a major goal, not everyone agrees on the best way to achieve it—and it can be especially challenging to ensure the “five rights” are accomplished consistently—right materials, right quantity, right location, right time, and right cost. Historically, asset-intensive companies (e.g., electric/gas utilities, mining, oil and gas) have a bit of a “checkered past” when it comes to managing inventory, specifically excess, obsolete, incorrect material, and/or wrong quantities in stock. That said, there is no doubt that when a piece of equipment goes down in one of these industries, everyone mobilizes to “get the oxcart out of the ditch” and ensure the asset is back online as quickly as possible. However, the systemic issues related to not having the right mix of inventory on hand can often go unaddressed as the pressures on asset management personnel compel them to have material on hand “just in case.” The real challenge then is determining what the right amount of inventory is for infrequently used items in an asset-intensive environment where downtime subtracts from net income. The primary objective of our most recent cross-industry supply chain benchmarking survey report is to provide industry practitioners with relevant and informative data to improve their strategic approach to inventory management and optimization. By providing lessons from other companies facing similar challenges across the globe, this report provides valuable insights for those seeking to master the science of inventory optimization. Effective inventory optimization improves performance, reduces cost, and boosts ROE.

Report Overview

The survey was designed to address three elements:

- Provide up-to-date information about the application of inventory optimization practices across asset-intensive industries

- Compare practices across several industries that maintain MRO inventory environments

- Review metrics for inventory and asset reliability to understand the relationship between a selection of inventory management practices and performance

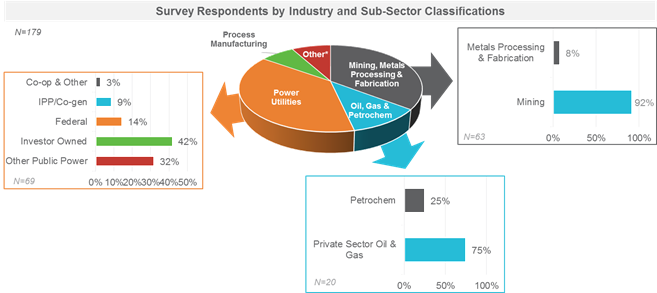

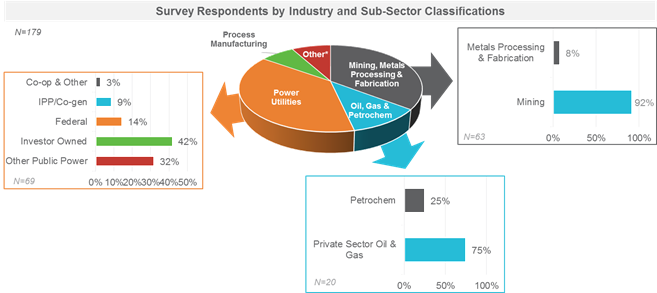

The survey questionnaire consisted of 11 questions focused on inventory optimization practices and three questions related to inventory and asset performance and was administered to more than 170 respondents in power utilities; mining, metals, processing & fabrication; oil, gas, and petrochemicals, and other industries.

Key Takeaways on Inventory Management

Inventory optimization is a cross-functional sport which requires the right practices (process, technology, etc.) to execute effectively and deliver high-performance results.

Optimization Practices

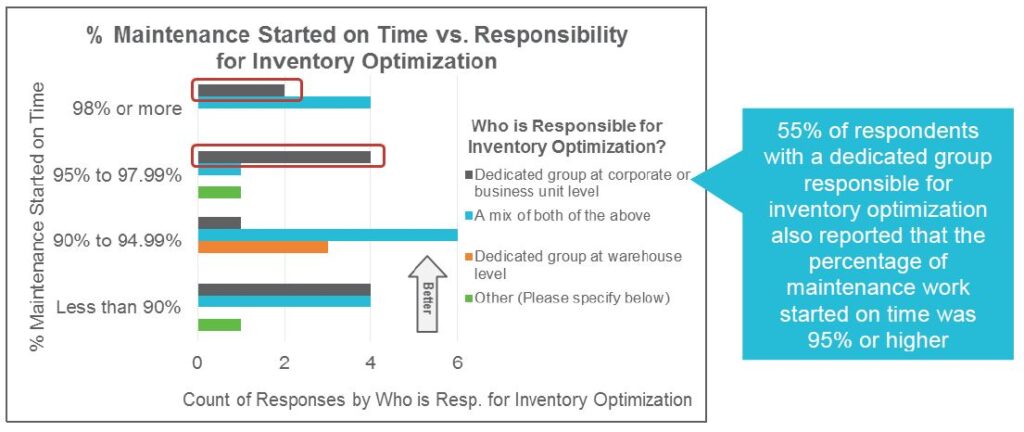

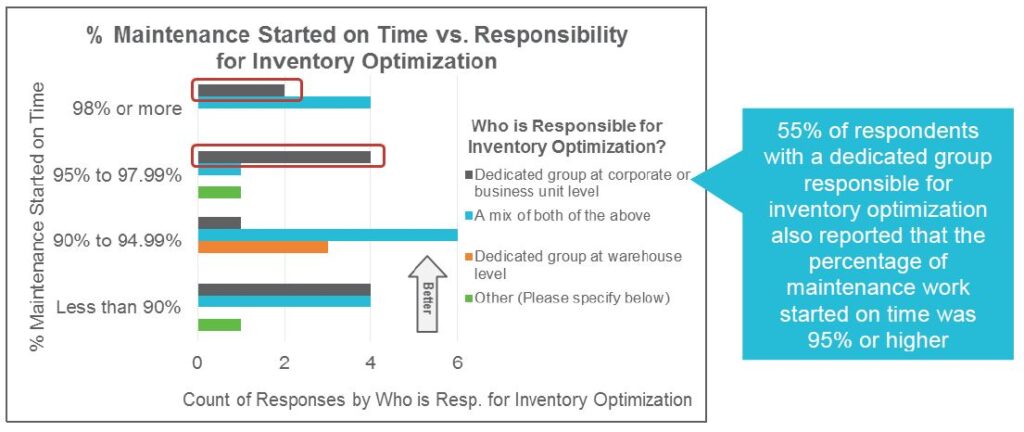

- Accountability for inventory optimization – The survey results indicate that companies, regardless of industry, assign responsibility for inventory optimization to individuals or groups within separate business units, though a growing percentage of respondents (30%) assign responsibility to a dedicated individual or group at the corporate or business unit level

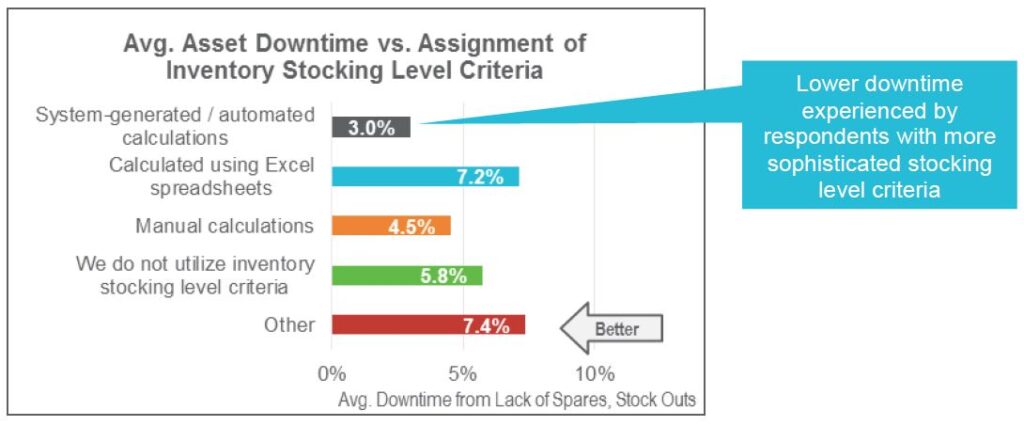

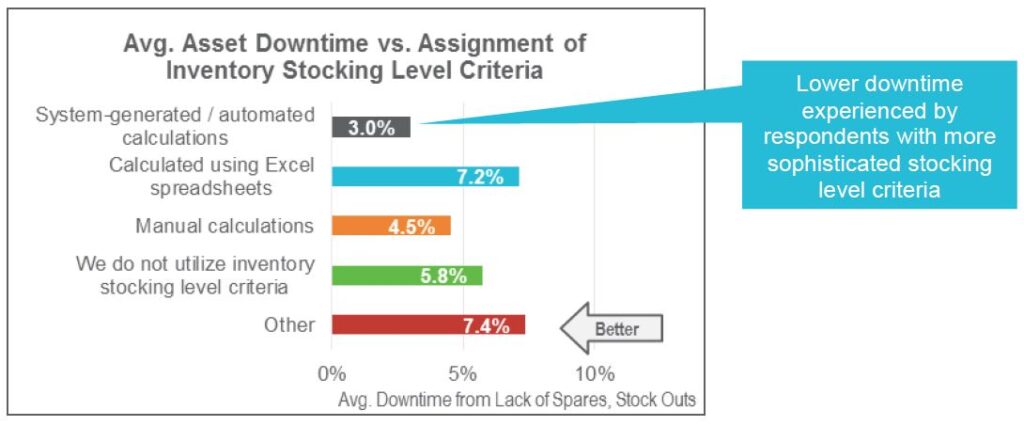

- Assignment of stocking level criteria – Approximately 50% of survey respondents across industries indicated some kind of system-generated or automated calculation to assign inventory stocking level criteria, while 24% of all participants still use manual calculations

- Reassessment of stocking level criteria – Frequency of inventory stocking level reassessment ranged widely from “every time a purchase is made” (21%) to “only when a stock out occurs” (5%), but the largest response category was “other” (31%) in which participants suggested that the reassessment frequency is driven by numerous factors that may vary depending on the type of inventory

- Degree of integration across materials management and other systems – The largest number of respondents indicated that the degree of integration between the materials management system and work order/asset management systems is “somewhat integrated” (44%). This indicates that challenges and barriers to “fully integrated” (the integration level reported by 36% of respondents) are common

Performance Metrics

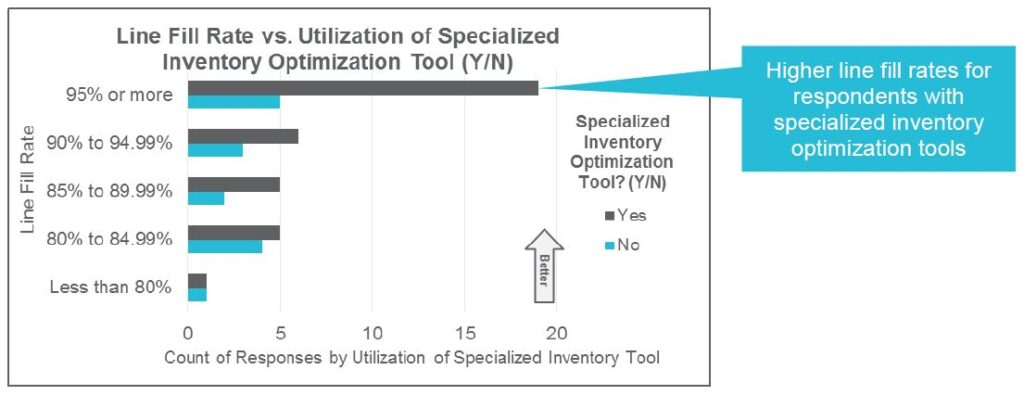

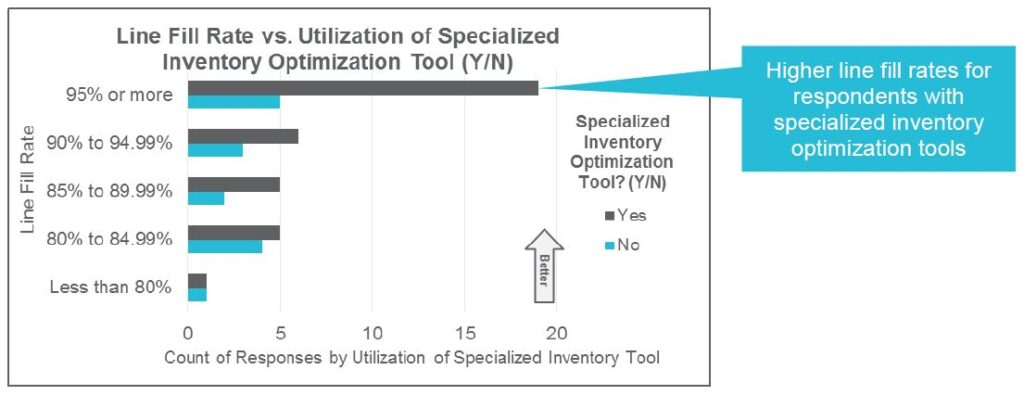

- Inventory performance metrics – More than half (53%) of all respondents across all industry groups use Inventory Turns Ratio, and less than a third use Line Fill Rate (32%)

- Asset performance metrics – Use of asset performance metrics varied by industry, with the most common metrics being:

- Mining, Metals Processing & Fabrication – Equivalent Availability Factor (33% adoption)

- Oil, Gas & Petrochemicals – % Production Lost Due to Unplanned Maintenance (50%)

- Power Utilities – Equivalent Availability Factor (16%)

- Process Manufacturing – Equipment Maintenance Cost % Compared to Total Operating Cost (15%)

- Performance metrics results

- Inventory Turns – Only 9% of respondents across all industries reported “3 or more,” and 40% of respondents in Oil, Gas & Petrochemicals and Power Utilities reported “less than 1”

- Line Fill Rate – 45% of respondents across all industries reported “95% or more,” driven by approximately 70% of Power Utilities respondents, but the remaining responses were evenly distributed across all other ranges from 80% to 94.99%

- Line Fill Rate for Critical Spares – 53% of all respondents reported “98% or more,” led by approximately 60% of Mining, Metals Processing & Fabrication respondents and approximately 50% of Power Utilities respondents

Inventory Practices vs. Inventory and Asset Performance – Illustrative Results

For More Information

The above information is just a sample of what the full survey report contains. To purchase a copy of the detailed survey results or to talk to us about your inventory management challenges, please contact Andy Flores, partner and supply chain practice lead at ScottMadden.

View More