Bruce Power’s 2,300-acre site on the shores of Lake Huron, Ontario, houses the Bruce A and B nuclear-generating stations; each holds four Canadian Deuterium Uranium (CANDU) reactors. All eight of the units are operational and producing more than 6,300 megawatts of clean, reliable, low-cost electricity, which is enough to power one in four hospitals, homes, and schools in Ontario. For six months, ScottMadden assisted this private nuclear energy generator with establishing an operational performance review (OPR) to improve station performance and increase accountability among the first-line supervisors.

The client wanted to implement a program where the first-line managers and the first-line supervisors had line-of-sight visibility to the key station performance metrics and an opportunity to develop their leadership skills. Bruce Power needed a program to achieve these two goals. Additionally, industry peers recommended that the station leadership team improve the accountability for results within the first-line managers and supervisors as a way to improve their operational performance and enhance the leadership. Because there were two nuclear stations at one site, there was an opportunity for both stations to develop the program together and learn from each other during accountability reviews.

ScottMadden was hired because of our previous experience in establishing successful accountability models with several U.S.-based nuclear operators. Additionally, ScottMadden had previously helped this client achieve tangible results while assisting them on operational improvement initiatives.

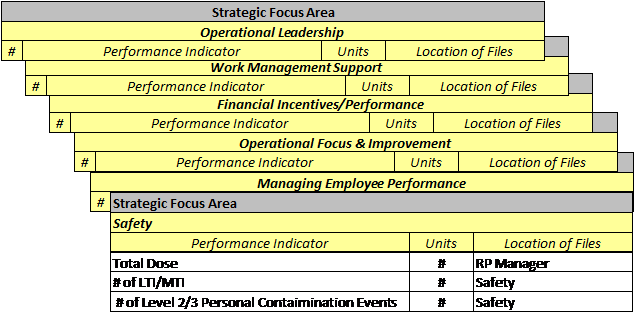

Bruce Power and ScottMadden shared the belief that the people were the key to success. So, in collaboration with Bruce Power, we set out to develop an OPR program that would be effective for the first-line managers and supervisors. ScottMaddencollaborated with the operations, maintenance, station leadership, and senior leadership teams to develop an OPR program leveraging the best practices in the industry. Based on best practices and our understanding of the client’s unique challenges, the program focused on six key performance areas: operational leadership, work management support, financial incentives and performance, operational focus and improvement, management of employee performance, and safety. We helped them articulate a set of 38 performance indicators, spanning these six key performance areas. An example of these performance indicators is shown in Figure 1. Every six weeks, each crew/division in operations and maintenance reported their results to station leadership. The OPR template and reporting tool was easily populated, maintained, and presented by the operations and maintenance crews’ leadership teams to station leadership and senior leadership. These sessions were designed to review performance and provide station leadership and senior leadership the opportunity to identify and recommend areas for improvement.

Figure 1: Performance Indicators to Be Reported On

.JPG)

ScottMadden assisted station leadership in communicating expectations through formal one-on-one meetings. ScottMadden then trained the operations and maintenance first-line managers and supervisors on how to navigate the tool, locate the necessary data, populate the appropriate fields, write appropriate corrective actions/remediation strategies, and conduct effective presentations to the intended audience.

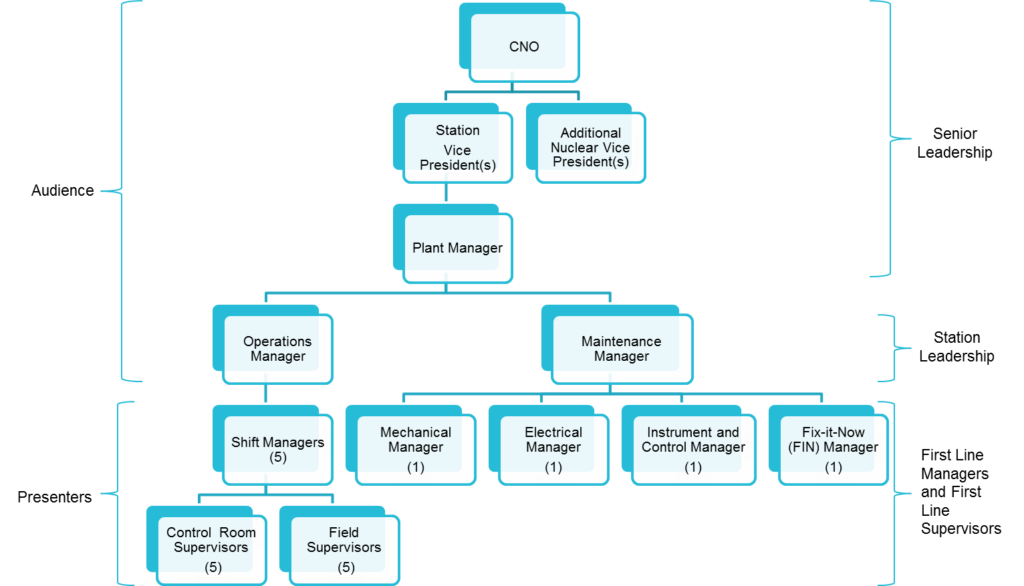

Finally, ScottMadden assisted the operations, maintenance, and station leadership teams in practice sessions to ensure the program was executed as desired. Lessons learned from these sessions were incorporated into the program to ensure continuous improvement. Additionally, as displayed in Figure 2, the leadership teams developed a forum to provide coaching. This structure enhanced accountability.

Figure 2: Operational Performance Review Program

First-line managers and supervisors were held accountable for their team’s results and critiqued on their team’s performance (where they had previously not been required to). The operations and maintenance leadership had a forum to provide feedback on their leaders’ performance against six key performance areas. First-line managers and supervisors in operations and maintenance gained experience preparing and delivering presentations to senior leaders from across the company. Those who needed additional development and coaching were identified, and coaching tools/techniques were discussed to help those employees improve their performance. Furthermore, good performers were more often recognized for their efforts. Operational results reduced station backlogs and improved financial performance and plant-operating conditions. Finally, industry peers provided feedback to the station leadership team that their OPRs were regarded as a significant contributor to improved operational performance and accountability at both stations.

“The operations OPR was developed several years ago to provide the operations manager a clear and concise report of individual crew performance. The template was very successful at ‘driving for results,’ which was part of the accountability model that contributed to Bruce B receiving its best ever INPO rating in 2012,” says Pierre Pilon, Plant Manager at Bruce B. “Today, the same template is used by all departments to provide a quarterly report of performance against targets to the senior leadership team.”

Sussex Economic Advisors is now part of ScottMadden. We invite you to learn more about our expanded firm. Please use the Contact Us form to request additional information.