Are inventory complexities, warehouse space, warehouse staffing, or inventory efficiency predictors of higher inventory levels?

Find out by accessing this complimentary report that leverages data from the Utility Materials Management Benchmarking Consortium (UMMBC) 2015 Warehouse Survey and offers our thoughts on a unique analysis to model quantifiable factors that contribute to generation inventory levels.

ScottMadden is a founding member of the UMMBC and has been conducting independent research studies on behalf of the consortium since 2007. ScottMadden has been assisting leading utilities with improving their supply chain operations for more than 20 years. Contact us to learn more about developing strategies to effectively reduce inventory levels.

Be sure to check out all of the articles in this series.

FULL ARTICLE

My inventory requirements are complex and drive me to keep a large number of unique parts, so it follows that I have higher inventory levels in my warehouse, right?

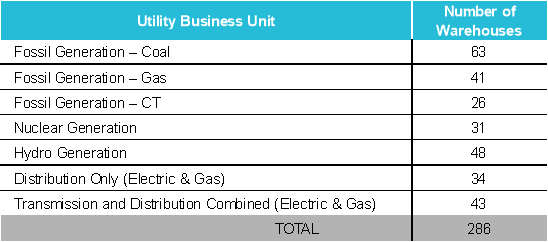

This article is the third in a series of articles examining common inventory management questions using statistical analysis of data compiled by the Utility Materials Management Benchmarking Consortium (UMMBC)[1] 2015 Warehouse Survey, which collected detailed data from 286 warehouses operated by 19 leading utilities. This article examines the validity of this common assumption and others related to inventory levels. Are inventory complexity, warehouse space, warehouse staffing, or inventory efficiency predictors of higher inventory levels? The data reveals the answers below.

Figure 1: Warehouse Participants by Business Unit

In the first article in this series, we examined the question of whether more inventory on hand improves material availability. Statistical analysis demonstrates that it does, but somewhat counterintuitively, not by much. The second article examined whether material availability impacts operating performance. Results revealed it does and more so than you might imagine. This article seeks to identify which factors contribute to higher inventory in generation warehouses. To answer this question, the research team focused on 161 non-hydro generation warehouse data sets, as this was the only utility subset with an adequate number of responses across all of the potential research variables.

The research team used “Total On-Site Material per MW” as the dependent variable.[2] Normalizing the volume of inventory by plant size (in this case, MW of generation) allowed the research team to control for the obvious impact of plant size. The following were selected as independent variables, or potential contributing factors to higher inventory:

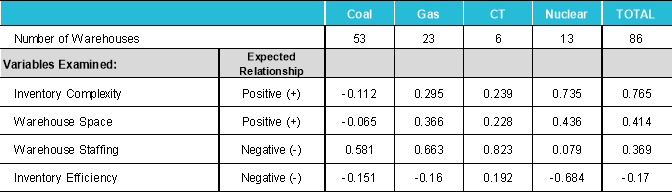

The team began by examining the relationship of each independent variable to the dependent variable. The tool used for this purpose was correlation analysis. Correlation is a statistical technique used to measure and describe the strength and direction of the relationship between two variables. A positive correlation indicates the extent to which those variables increase or decrease in parallel, while a negative correlation indicates the extent to which one variable increases as the other decreases.[5] Correlation coefficients can range from -1.0 to +1.0, depending upon the strength and direction of the relationship. The correlation coefficients for the variables described above are presented in Figure 2.

Figure 2: Correlations Between $ Value of Total On-Site Material/MW

and Selected Warehouse Variables

Based upon the correlation coefficients for all 86 plants taken together, it appears that the direction (+/-) of the expected relationship proved true for the following three relationships:

However, warehouse staffing was not correlated with inventory levels as we expected. Instead, more warehouse staff appears to be associated with more inventory despite the fact that warehouse staffing levels were normalized for plant size.

The strength of the relationship was relatively strong for all variables except inventory efficiency.

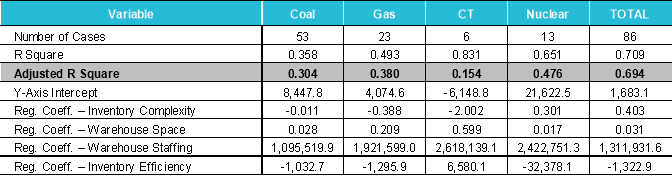

Having examined the individual relationship between each of the variables and inventory levels, the research team then attempted to examine the combined impact of all five variables working together. The tool used for this purpose was multiple regression analysis.[6] Multiple regression is a statistical technique used to measure the relationship between one dependent variable and several independent variables operating in unison. It attempts to measure the individual impact of each variable after controlling for any correlations between the variables themselves. The results are shown in Figure 3.

Figure 3: Multiple Regression Results for $ Value of Total On-Site Material/MW

and selected Warehouse Variables

When viewed as an integrated model, the four variables examined “explain” 69.4% of the variation in the $ Value of Total On-Site Material/MW based upon the value of the Adjusted R Square.[7] This is a relatively robust model, and for real-world phenomena, which are usually messy, 69.4% is a very strong result. On the flip side, our model still leaves approximately 30% of the variation in material levels unexplained. These unexplained variables likely include: warehouse policies and practices, the sophistication of the inventory management software used, the training and experience of the materials management team, and the company’s focus on inventory management in general.

To the best of our knowledge, the analysis described in this article is the first attempt to model quantifiable factors that may contribute to generation inventory levels. The results indicate that the variables examined explain approximately 70% of the variation in inventory levels and that the following relationships hold true:

The clear take-away is that simplifying the number of different SKUs and increasing inventory turnover rates contribute to reduced inventory levels. It is less clear as to exactly why more warehouse staff per MW contributes to more material on site per MW since both variables are normalized for plant size. Our working theory, not yet tested by additional research, is that in some cases more staff is correlated with poorer inventory management practices. That is, in the absence of a clear understanding of service-level or operational performance deficiencies, companies throw people at perceived problems. This can result in continuing sub-par performance with the added burden of increased costs. In any case, increasing warehouse staff does not seem to be an effective approach to reducing inventory levels.

ScottMadden’s long history of working with electric utilities and other asset-intensive companies and deep understanding of the key performance levers in supply chain gives us a clear lens through which to view efficiency and effectiveness. Additionally, ScottMadden’s proven methodology to uncover the true drivers of inventory levels and develop realistic improvement plans is the most comprehensive approach in the industry. We encourage you to learn more about our capabilities and opportunities to optimize your inventory levels.

To learn more about ScottMadden’s supply chain practice, please contact us.

We know energy from the ground up. Since 1983, we have been energy consultants. We have served more than 300 clients, including 20 of the top 20 energy utilities. We have performed more than 2,400 projects across every energy utility business unit and every function. We have helped our clients develop strategies, improve operations, reorganize companies, and implement initiatives. Our broad and deep energy utility expertise is not theoretical—it is experience based.

[1] The UMMBC was established in 2007 and currently consists of 56 leading utilities who periodically collaborate to develop information needed to critically examine and improve ongoing warehouse and inventory management operations in the electric & gas utility industry. Members participate in individual surveys on a voluntary basis. Comprehensive warehouse surveys were conducted in 2008, 2011, and 2015.

[2] Total On-Site Materials includes FERC 154 inventory, consigned materials, and non-costed capitalized material.

[3] Warehouse staff includes warehouse management, materials management analysts and coordinators, materials management storekeepers, material handlers, materialmen and materials management (tool room personnel), materials quality control, and administrative personnel.

[4] Inventory Turnover Rate is defined as the Total $ Value of Inventory Issued during the year divided by the Total Value of All Inventory on Site.

[5] In preparing this analysis, the research team used the Pearson product-moment correlation coefficient, which measures the strength of the linear association between variables. Line plots were examined in each case to determine if a non-linear relationship might exist.

[6] Multiple linear regression (MLR) is a statistical technique that used several explanatory variables to predict the outcome of a response variable. The goal of MLR is to mode the relationship between the explanatory and response variables.

[7] R-square measures the proportion of the variation in the dependent variable (Y) explained by the independent variables (Xn) for a linear regression model. Adjusted R-square modifies the statistic based upon the number of independent variables in the model, giving a better predictor of true modeling accuracy.

Sussex Economic Advisors is now part of ScottMadden. We invite you to learn more about our expanded firm. Please use the Contact Us form to request additional information.